International Thermal Systems

Thermal Process Industrial Ovens and FurnacesInternational Thermal Systems is an original equipment manufacturer of thermal process industrial ovens and furnaces in batch and continuous flow equipment and aqueous industrial parts washers. ITS is headquartered in Milwaukee, Wisconsin, USA and was formed by the merger of Industrial Heat Enterprises International (IHEI), Oven Systems Incorporated (OSI), LTG Technologies, Inc. and Continental Equipment Corporation offering over 90 years of industrial equipment engineering and manufacturing expertise.

ITS manufactures state of the art equipment engineered with rugged and structural designs for years of trouble free service. ITS ovens and furnaces are used in a wide variety of heat processes including composite curing, drying, aging, annealing, solution heat treating, stress relieving, bonding, tempering, preheating and forming. ITS aqueous parts washers in a variety of standard sizes and configurations. Industries served include aerospace, automotive, agriculture, electronic, power generation, defense, military, textiles, building products, foundry, mining and more.

ITS equipment is backed by an excellent customer service department, providing R & D, installation and startup, retrofits, repairs, preventative maintenance and technical support performed by factory trained technicians. The ITS parts department maintains a stock of replacement and spare parts for all equipment.

TruTemp Batch Oven

ITS TruTemp Batch Ovens are built in standard walk-in sizes and custom designs, with standard models to temperatures of 500 F and custom models to 1000 F. Features included gas or electric heating, patented three-five airflow technology for temperature uniformity of +/- 5 F, rugged aluminized steel construction, top quality parts and controls for precise process control and operation. ITS has years of experience manufacturing batch ovens to meet our customer’s specific industrial process heating requirements. For applications requiring drying, curing, aging, pre-heating, stress-relieving and more to serve industrial markets including aerospace, defense, automotive, medical and rubber processing to name a few. For additional specifications open pdf brochure for a list of standard sizes and contact our office to discuss your next project.

DOWNLOAD

TruTemp Conveyor Oven

ITS Conveyor Ovens are designed for rapid thermal processing and continuous operation requirements. Available in standard pre-engineered or custom built designs with features including efficient electric heat for precise temperature control to 500 F, multiple heat zones and cooling, top-down directed airflow for maximum heat transfer. Used in a variety of applications including aging, annealing, curing, drying, preheating, heat shrinking, tempering and more. For additional specifications and standard sizes open pdf brochure and contact our office to discuss your needs.

DOWNLOAD

TruTemp Composite Curing Oven

ITS TruTemp Composite Curing Ovens provide an economical out of autoclave solution for the thermal processing of composite parts. With standard features of gas or electric heating, process temperatures to 650 F, adjustable ductwork with horizontal and combination airflow for tight temperature uniformity and optimal part heating, multiple thermocouple ports and vacuum systems, programmable process controls for recipe storage and data acquisition to meet NADCAP, AS9100 and AMS2750 requirements. ITS builds quality equipment to support this growing industry for parts used in aerospace, defense, medical, sports, fitness and performance racing. See pdf brochure for more information and contact our office to discuss your requirement.

DOWNLOAD

TruTemp Box Furnace

ITS TrueTemp Box Furnaces are designed and manufactured for heat treating requirements. Standard features include gas and electric heating, heavy plate construction, energy efficient ceramic fiber insulation, standard operating temperatures to 2000 F, 3300 F custom designs, standard temperature uniformities of +/- 25 F, custom designs to +/- 5 F. ITS has years of experience building box furnaces for a variety of applications including; annealing, hardening, softening, normalizing, preheating, stress relief and tempering, serving aerospace, automotive, petrochemical, steel mills and more. See pdf brochure for standard box furnace sizes and contact our office for your equipment needs.

DOWNLOAD

ITS Stress Relief Furnace

ITS Stress Relief Furnaces are designed to relieve stress in materials caused by welding, machining, cold forming or another heat process. Equipment features high efficiency gas or electric heating, robust structural and thermal insulated construction, operating temperature ranges to 1800 F, inert atmosphere options, custom designed to meet specific applications and customer requirements. ITS offers years of experience building stress relief furnaces for the aerospace, automotive, electronics, heavy equipment industry and more. See pdf brochure below for more specifications and contact our office to discuss your equipment needs.

DOWNLOAD

ITS Drop Bottom Aluminum Heat Treat Furnace

ITS Drop Bottom Aluminum Heat Treat Furnaces are designed for processes requiring fast heat up and recovery rates, specializing in large workspace and heavy workloads. Standard features include high efficiency gas direct and indirect heating or electric heating, robust structural and thermal insulated construction, tight temperature uniformity for operating temperatures of 300 F to 1200 F, heavy duty front quench tank, water/glycol with load and unload station, industry specifications to meet AMS, MIL, NADCAP, and CQ19, standard and custom designs to meet specific customer requirements. For aging and annealing applications, ITS serves the aerospace, automotive, military industry and more to meet their heat treating equipment needs. See pdf brochure for more information and contact our office to review your equipment needs.

DOWNLOAD

ITS Drop Bottom Aluminum Heat Treat Furnace

– PDF

TruTemp Car Bottom Furnace

ITS TruTemp Car Bottom Furnaces are designed for processing of large and heavy material loads. Standard features include high efficiency gas or electric heating, robust structural and thermal insulated construction, operating temperature ranges to 2800 F, temperature uniformity requirements to meet API, standard temperature uniformity to +/- 15 F, standard and custom designs. Process applications include heat treating, homogenizing, annealing, preheating and stress relieving for a variety of materials including aluminum, steel, cast iron, titanium and more. ITS services the process equipment needs of the aerospace, automotive, heavy equipment, petrochemical, military industries and more. See pdf brochure for more information and contact our office to discuss your equipment needs.

DOWNLOAD

TruTemp Car Bottom Furnace – PDF

International Thermal Systems

Industrial Parts WashersInternational Thermal Systems industrial parts washers are designed and manufactured to clean parts in all shapes and sizes to remove chemicals, oils or dirt using environmentally safe aqueous water based cleaning solutions. ITS serves all industries including aerospace, automotive, metal machining, casting and stamping, food services and more. The ITS cleaning equipment is available in standard and custom designs with the ITS TruClean brand. Models include conveyor washers, front and top load cabinet washers, monorail washers, rotary drum washers, case washers and pallet washers. With the variety of ITS washing systems available, standard models suit many of our customer’s needs, providing an economical solution with shorter lead times. For applications that present a greater challenge with complex part designs, cleanliness requirements, drying, material handling or to integrate with existing manufacturing operations, ITS can provide a custom solution. ITS offers a complete R&D lab to test wash parts, service and parts department. Below is additional information on the TruClean models and pdf files with complete specifications for the standard models. Please contact our office to answer any questions and review your parts cleaning requirements.

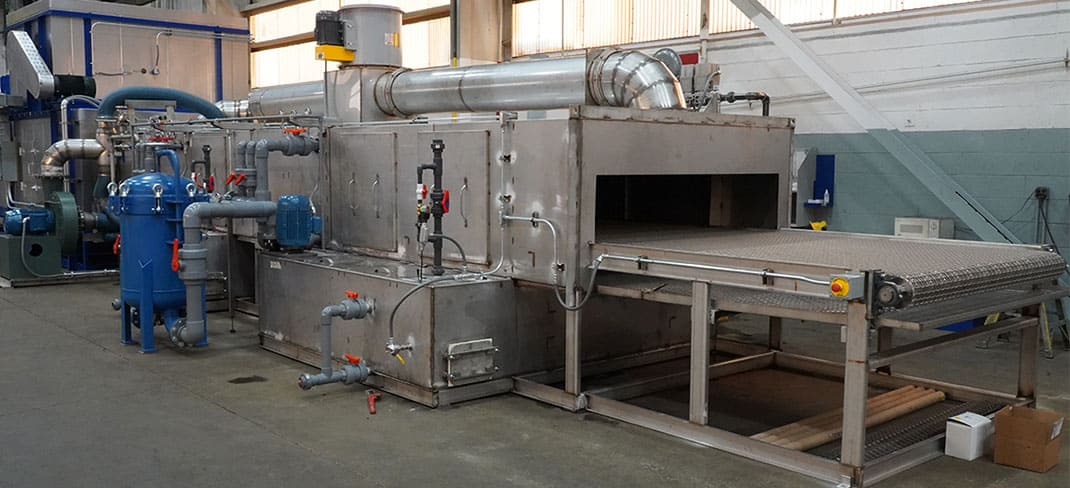

Conveyor Washers

International Thermal Systems TruClean conveyor washers provide a continuous cleaning process with belt driven designs available in 4 standard belt sizes. The pre-engineered models offer a long list of standard features including stainless steel construction, high velocity spray nozzles, marine style tank clean out doors, ambient blow off and PLC / HMI controls. All is equipment is manufactured with quality, durability and low maintenance in mind. For applications requiring additional features and engineering, custom designs are available.

DOWNLOAD

Cabinet Washers

International Thermal Systems cabinet washers are designed for manual or assisted loading of parts in various parts and sizes for lower production requirements. The TruClean cabinet washers are available in several standard top load and front load models. Top load models feature a horizontal hinged lid with stationary process basket and high velocity rotating spray nozzles for 360 degrees of cleaning, ideal for smaller parts and production batches. To accommodate larger batches or parts the front load models feature a hinged vertical door for side loading onto a rotating process table, stationary high velocity spray nozzles provide 360 degrees of cleaning. See pdf brochures below for complete list of standard features and options.

Monorail Washers

International Thermal Systems monorail washers are designed for high production rates using a variety of monorail systems and hanger designs to clean a variety of parts and sizes. Systems can be stand-alone or integrated into existing production lines and manufacturing operations. All equipment is designed and built for a specific application. Standard models feature external or internal mount monorail systems, pre-wash, single or multi wash and rinse stages, ambient or heated blow-off and drying stages. The hangers are custom built to securely hold parts and eliminate any damage to parts. See pdf brochure for additional features and options.

DOWNLOAD

Case Washers

International Thermal Systems case washers are designed to clean a variety of dairy, beverage and tote boxes. Single and double lane designs with zig-zag guide rails and powerful jet spray nozzles ensure a thorough cleaning of all surfaces. Standard features include stainless steel construction, ambient or heated solution tanks, cast iron or stainless steel solution pumps and more. See pdf brochure for additional features and options.

DOWNLOAD

Pallet Washers

International Thermal Systems pallet washers are designed to clean reusable pallets, totes and trays. Standard single lane design allows for easy loading of pallets onto belt conveyor. The powerful jet spray nozzles are positioned to clean all pallet surfaces with air blow off to remove moisture. Standard features include stainless steel construction, marine style clean out doors, electric wash solution heat, NEMA 12 control panel, variable speed control and more. See pdf brochure for additional features and options.

DOWNLOAD

Rotary Drum Washers

International Thermal Systems continuous rotary drum washers are designed to clean small to medium parts in a batch process, metal fasteners, stampings, machined or electrical parts. The rotary drum design provides a complete thorough cleaning process with gentle tumbling, immersion and spray, drain and drying of the most intricate or detailed parts. Standard features include heavy duty drum, stainless steel construction, ambient and heated solution tanks, slopped solution tank bottoms for easy discharge and cleaning, NEMA 12 control panel and more. See pdf brochure for more features and options.

DOWNLOAD

Rotary Drum Washers – PDF

Need More Information?

Let us know what we can assist you with