Nexthermal

Nexthermal is a manufacturer of Process Electric Heaters for the Plastic Processing, Packaging and Rubber Industries and Original Equipment ManufacturerNexthermal is a world leading manufacture of process electric heating elements specializing in made to order cartridge heaters, coil heaters, flexible tubular heaters, cast in heaters, complete assemblies and more. With decades of experience engineering and designing electric heating elements, Nexthermal offers some of the tightest tolerances in the industry and is a proven solution provider for industrial electric heaters. Their top quality manufactured products are back by excellent customer service department, engineering, technical support, short lead times and competitive pricing. As an authorized distributor of the Nexthermal heaters we see this with loyal customers and repeat business. We service a variety of industries including injection molding, extrusion, packaging, rubber pharmaceuticals, die casting and OEM’s of all types of equipment for medical, electronics, defense, automotive and more. Applications and processes include injection mold nozzles and manifolds, plastic extrusion dies, tools and manifolds, sealing jaws and seam sealing for form fill and seal packaging equipment, thermoforming molds and platens, rubber compression molds and platens, wedge injection tools for softgel capsules, injection nozzles for die casting, tooling for OEM equipment and more. We look forward to an opportunity to work with you on your next heating requirement. Whether it’s to replace or improve a heater design for an existing machine or application or a new project. Below are standard specifications for the Nexthermal heaters and pdf brochures for your review. Please contact our office with any questions and to discuss your needs.

Cartridge Heater Standard

- Medium and High Watt Density’s

- Diameters of .125” to 1” (6.2 mm to 20.0 mm)

- Lengths of 1” to 100.0” (25.4 mm to 2540 mm)

- Sheath Materials of SS321 and Incoloy 800

- Lead materials, Fiberglass, Silicone and Teflon

- Lead protection, Fiberglass Sleeve, Braided Metal Sleeve, Armor Cable

- Potting Options, Ceramic, Epoxy, Teflon Plug, Silicone

- Exit Options, Right Angle, Right Machined Low Profile or Block

- Additional Options, Centerless Grind Diameters, Distributed Wattage, Moisture Resistance, Anti-Seize Coating, Removal Aids, Flanges, NPT Fittings and Internal Thermocouples.

DOWNLOAD

Cartridge Heater Standard – PDF

Coil Heater Standard

- Coil Heater Types, Mini, Maxi, Hotlock, Axial Clamp, Embedded in Brass, Pressed on Sheath

- Profiles, Flat, Round and Square from 0.039” x .067” (1.0 mm x 1.7 mm) to 0.181” x .338” (4.6 mm x 8.6 mm)

- Inside Diameters from 0.236” (6.00 mm) to 0.80” (20.99 mm)

- Sheath Materials of SS321 and Nickel

- Leads materials, Teflon and Fiberglass, Standard and High Temperature

- Lead Protection, Fiberglass Sleeve, Braided Metal Sleeve, Armor Cable

- Various Standard Exit Options

- Additional Options, Wind from Stock Sizes, Moisture Resistant Transition Head, Compact Transition Head, Internal Thermocouples, Formed to Groove

DOWNLOAD

Coil Heater Standard – PDF

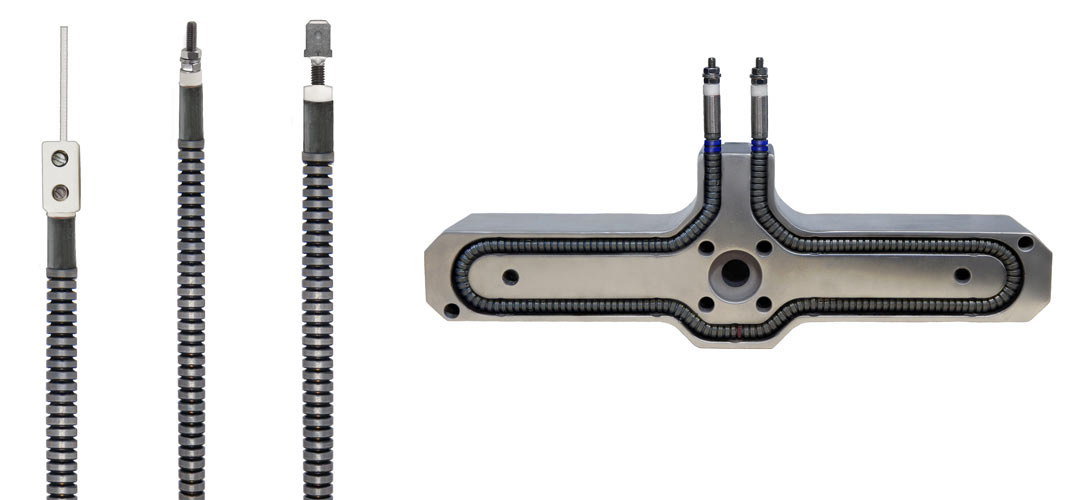

Nextflex Flexible Tubular Heater

- Nextflex Flexible Types and Diameters, 6.5 mm Round, 8.0 mm Round, 8.5 mm Low Watt and 8.5 mm D-Shape

- Lengths from 300 mm to 2100 mm

- Additional Options, Large Stock Inventory, Installation Tools, Custom Designs

DOWNLOAD

Nextflex Tubular Heater Standard – PDF

Need More Information?

Let us know what we can assist you with